Beijing Zhongke Jian'an (Hebei) Medical Technology Co., Ltd.

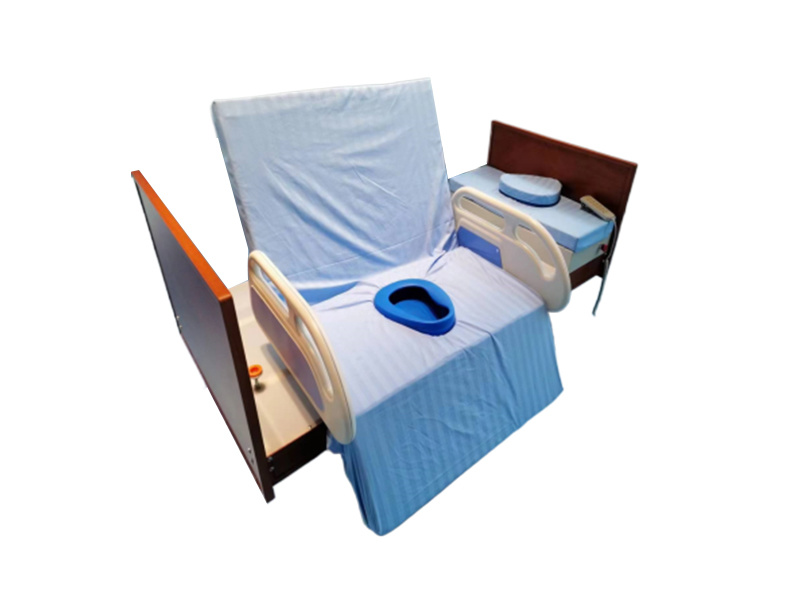

Common Faults and Treatment Methods of Electric Nursing Bed

Release time:

2023-11-07

Problem one: motor failure Performance: nursing bed can not lift, adjust the angle, etc. • Cause: motor damage, circuit failure, overload use, etc. • Countermeasures: • Check whether the circuit connection is normal and whether there is any looseness or short circuit. • If the motor is damaged, replace it with a new one. • Remind the user to avoid overload and operate according to the specified load weight. For example, a user reported that the lifting function of the nursing bed failed, and the after-sales personnel found that the circuit was loose and returned to normal after reconnection. Problem two: remote control handle failure • Performance: Unable to control the movement of the nursing bed through the control handle. • Cause: The battery is dead, the power supply is dead, and the line is faulty. • Countermeasures: • Replace the control handle. • Check the power supply for electricity. • Power-up lines are damaged. For example, a user said that the control handle could not control the nursing bed. After detection, the power supply was dead. The problem was solved after replacing the new socket. Problem three: loose bed structure • Performance: The bed board shakes and there is abnormal noise at the joint. • Cause: Long-term use leads to loose screws and wear of parts. • Countermeasures: • Tighten the screws and check the connection parts. • Replace or repair worn parts. For example, some users reported that the bed board was shaking when the nursing bed was in use, and the after-sales personnel found that the screws were loose and the problem was solved after fastening. Question four: mattress deformation • Performance: mattress loses elasticity, affecting comfort. • Cause: use time is too long, mattress quality problems. • Countermeasures: • Replace the mattress with a new one for the user according to the warranty. • Users are advised to regularly flip the mattress to extend its life. For example: a user to buy a nursing bed mattress in use after a period of deformation, after-sales for its replacement of the new mattress, and inform the correct use and maintenance methods. Question 5: excessive noise • Performance: abnormal noise is generated when the motor is running or the bed is moving. • Cause: lack of lubrication of parts, failure of mechanical parts. • Countermeasures: • Lubricate and maintain related parts. • Troubleshoot and repair faulty mechanical components. For example: the user reflects that the nursing bed is very noisy when adjusting the angle, and the noise is obviously reduced after the after-sales personnel add lubricating oil.

Problem one: motor failure

Performance: nursing bed can not lift, adjust the angle, etc.

• Cause: motor damage, circuit failure, overload use, etc.

• Countermeasures:

• Check whether the circuit connection is normal and whether there is any looseness or short circuit.

• If the motor is damaged, replace it with a new one.

• Remind the user to avoid overload and operate according to the specified load weight.

For example, a user reported that the lifting function of the nursing bed failed, and the after-sales personnel found that the circuit was loose and returned to normal after reconnection.

Problem two: remote control handle failure

• Performance: Unable to control the movement of the nursing bed through the control handle.

• Cause: The battery is dead, the power supply is dead, and the line is faulty.

• Countermeasures:

• Replace the control handle.

• Check the power supply for electricity.

• Power-up lines are damaged.

For example, a user said that the control handle could not control the nursing bed. After detection, the power supply was dead. The problem was solved after replacing the new socket.

Problem three: loose bed structure

• Performance: The bed board shakes and there is abnormal noise at the joint.

• Cause: Long-term use leads to loose screws and wear of parts.

• Countermeasures:

• Tighten the screws and check the connection parts.

• Replace or repair worn parts.

For example, some users reported that the bed board was shaking when the nursing bed was in use, and the after-sales personnel found that the screws were loose and the problem was solved after fastening.

Question four: mattress deformation

• Performance: mattress loses elasticity, affecting comfort.

• Cause: use time is too long, mattress quality problems.

• Countermeasures:

• Replace the mattress with a new one for the user according to the warranty.

• Users are advised to regularly flip the mattress to extend its life.

For example: a user to buy a nursing bed mattress in use after a period of deformation, after-sales for its replacement of the new mattress, and inform the correct use and maintenance methods.

Question 5: excessive noise

• Performance: abnormal noise is generated when the motor is running or the bed is moving.

• Cause: lack of lubrication of parts, failure of mechanical parts.

• Countermeasures:

• Lubricate and maintain related parts.

• Troubleshoot and repair faulty mechanical components.

For example: the user reflects that the nursing bed is very noisy when adjusting the angle, and the noise is obviously reduced after the after-sales personnel add lubricating oil.

FAQ

Common Faults and Treatment Measures of Electric Bath Bed

The following are the common problems and corresponding countermeasures that may occur after the sale of electric bathing beds: Problem one: water leakage • Performance: During use, water leaks from the edge of the bed and the sewer pipe. • Cause: aging of the seal, aging of the water-avoiding cloth, and the connection is not tight. • Countermeasures: • Check and replace aging seals. • Repair or replace broken water-repellent cloth. • Re-tighten connections to ensure tight connections. For example, a user found that the bath bed was leaking when in use, and the after-sales personnel found that the water cloth was aging after checking. The problem was solved after replacing the new water cloth. Problem two: electric component failure • Performance: The electric lifting function of the bed does not work properly. • Cause: motor damage, circuit problem, control module failure. • Countermeasures: • Check whether the motor is running normally, and replace the motor if it is damaged. • Check the circuit for open circuit, short circuit, etc. and repair it. • If the control module fails, replace the control module with a new one. For example, a user feedback that the bath bed cannot be lifted or lowered. After detection, the circuit is broken and the normal function is restored after the circuit is repaired. Question three: bed rust • Performance: Rust appears on the surface of the bed. • Cause: long-term wet environment, surface coating damage. • Countermeasures: • Grind the rust and recoat it. • Remind users to keep the environment around the bath bed dry to avoid long-term water accumulation. For example, if the user finds that some metal parts of the bath bed are rusted, the after-sales personnel polish the rust and re-do the anti-rust treatment, and inform the user to pay attention to moisture-proof. Problem four: control panel failure • Performance: Unable to operate the functions of the bath bed through the control panel. • Cause: key damage, control panel wiring fault. • Countermeasures: • Replace the damaged keys. • Examine and repair control panel wiring. For example: a user said that some keys on the control panel did not respond, after-sales personnel replaced the damaged keys, the control panel returned to normal.

2023-11-07

Common Faults and Treatment Measures of Electric Shift Machine

Fault one: power supply problem Performance: unable to boot, abnormal power display. • Cause: battery damage, charger failure, loose power line. • Treatment: • Check whether the battery is aged or damaged, and replace it with a new one if necessary. • Confirm whether the charger can work normally, if not, replace the charger. • Check the power line connection to ensure that the line is stable and not loose. For example, a user's electric shift machine cannot be turned on. After inspection, it was found that the battery was aging and returned to normal after replacing the battery. Fault two: the movement is not smooth • Performance: The shift machine is stuck and has great resistance when moving. • Cause: wheel damage, foreign matter on the ground. • Treatment: • Check whether the wheels are worn or deformed, and replace the damaged wheels in time. • Clear debris and obstacles from the track. For example, when a certain displacement machine moved, it was obviously stuck. The inspection found that there were sundries in the track, and the movement recovered smoothly after cleaning. Fault three: lifting or lowering fault • Performance: unable to lift or descend normally, abnormal lift/descent speed. • Cause: electric push rod failure, control system problems. • Treatment: • Check whether the electric push rod is normal, repair or replace the faulty electric push rod. • Detect control system components and wiring, repair or replace faulty components. For example, there is user feedback that the shift machine is slowly lifted. After investigation, it is a wiring problem. After replacing the control box, it returns to normal. Fault four: sling damage • Performance: The sling is torn, worn and broken. • Reason: long-term use wear, overload use. • Treatment: • Replace damaged slings in time to ensure safe use. • Remind the user to use the shift machine according to the specified load weight. For example, the user found that the sling was worn, and after-sales replaced it with a new sling, and informed the correct use method and precautions. Fault five: excessive noise • Performance: The shift machine produces abnormal noise during operation. • Cause: lack of lubrication of mechanical parts, loose parts. • Treatment: • Lubricate and maintain the relevant mechanical parts. • Tighten loose parts. For example: a shift machine is very noisy, after lubrication and fastening treatment, the noise is significantly reduced.

2023-11-07

Common Faults and Treatment Methods of Electric Nursing Bed

Problem one: motor failure Performance: nursing bed can not lift, adjust the angle, etc. • Cause: motor damage, circuit failure, overload use, etc. • Countermeasures: • Check whether the circuit connection is normal and whether there is any looseness or short circuit. • If the motor is damaged, replace it with a new one. • Remind the user to avoid overload and operate according to the specified load weight. For example, a user reported that the lifting function of the nursing bed failed, and the after-sales personnel found that the circuit was loose and returned to normal after reconnection. Problem two: remote control handle failure • Performance: Unable to control the movement of the nursing bed through the control handle. • Cause: The battery is dead, the power supply is dead, and the line is faulty. • Countermeasures: • Replace the control handle. • Check the power supply for electricity. • Power-up lines are damaged. For example, a user said that the control handle could not control the nursing bed. After detection, the power supply was dead. The problem was solved after replacing the new socket. Problem three: loose bed structure • Performance: The bed board shakes and there is abnormal noise at the joint. • Cause: Long-term use leads to loose screws and wear of parts. • Countermeasures: • Tighten the screws and check the connection parts. • Replace or repair worn parts. For example, some users reported that the bed board was shaking when the nursing bed was in use, and the after-sales personnel found that the screws were loose and the problem was solved after fastening. Question four: mattress deformation • Performance: mattress loses elasticity, affecting comfort. • Cause: use time is too long, mattress quality problems. • Countermeasures: • Replace the mattress with a new one for the user according to the warranty. • Users are advised to regularly flip the mattress to extend its life. For example: a user to buy a nursing bed mattress in use after a period of deformation, after-sales for its replacement of the new mattress, and inform the correct use and maintenance methods. Question 5: excessive noise • Performance: abnormal noise is generated when the motor is running or the bed is moving. • Cause: lack of lubrication of parts, failure of mechanical parts. • Countermeasures: • Lubricate and maintain related parts. • Troubleshoot and repair faulty mechanical components. For example: the user reflects that the nursing bed is very noisy when adjusting the angle, and the noise is obviously reduced after the after-sales personnel add lubricating oil.

2023-11-07